The smoulder temperature describes the flammability behaviour of a flat dust layer on a hot surface. It is defined as the lowest temperature of a heated, free-standing surface which is capable of igniting a 5 mm thick dust layer.

Smoulder temperature

Experience has shown that combustible dusts, when deposited in heaps or layers, may under certain circumstances develop internal combustion and high temperatures. This is due to the porous structure of dust deposits, which gives oxygen access to the particle surface throughout the deposit, and also makes the heat conductivity of the deposit low. Consequently, heat developed due to comparatively slow initial oxidation at moderate temperatures inside the dust deposit, may not be conducted into the surroundings sufficiently fast to prevent the temperature in the reaction zone from rising. As long as oxygen is still available, the increased temperature increases the rate of oxidation, and the temperature inside the deposit increases even further.

Mostly this occurs when the dust deposit or layer rests on a heated surface, which supplies the heat needed to trigger self-ignition in the dust. Such surfaces can be overheated bearings, heaters in workrooms, light bulbs, walls in dryers, etc.

If a dust deposit containing such a reaction zone, often called a 'smouldering nest', is disturbed and dispersed by an air blast or a mechanical action, the burning dust can easily initiate a dust explosion if brought in contact with a combustible dust cloud. Sometimes the dust in the deposit that has not yet burnt, forms the explosible dust cloud.

The smoulder temperature can be used to limit the temperature of surfaces on which dust layers form to safe values.

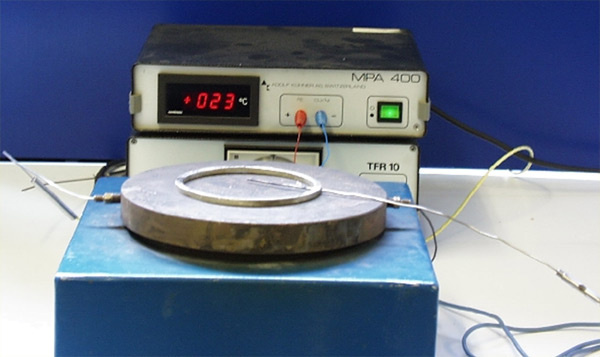

The apparatus consists of an electrically heated circular plate made out of copper (diameter 200 mm, thickness ≥ 20 mm, electric power 2 to 3 kW), a temperature controller, three thermocouples and a temperature recorder for the plate and sample temperature.

With the help of a ring, a dust layer having a 100 mm diameter and a 5 mm thickness is deposited on the copper plate. Through a hole in the metal ring a thermocouple is inserted into the dust layer at a distance of 2 to 3 mm above the hot plate. The point of measurement is located in the centre of the dust layer.

Following the recommended procedure, ignition shall be considered to have occurred if:

(a) visual glowing or flames are observed, or

(b) a temperature of 450 ° C is measured, or

c) a temperature rise of 250 ° C above the temperature of the heated plate is measured.

The lowest (plate) temperature rounded to an even 10°C which will just result in a smouldering appearance or ignition will be defined as the smoulder temperature.

With regard to b) and c) above, ignition shall not be considered to have occured i fit can be shown that the reaction does not propagate to glowing or flaming.

The lowest (plate) temperature rounded to an even 10°C which will just result in a smouldering appearance or ignition will be defined as the smoulder temperature.

If smoke is formed a heated platinum wire (approx. 1000°C) is used to determine whether or not this smoke can be ignited.

The test is performed on the sample fraction having a particle size less than 200 µm.

The smoulder temperature can only be determined for those dusts, which do not decompose, melt or evaporate before reaching the appropriate temperature for smouldering to occur.

The value of the smoulder temperature depends on the thickness of the dust layer and decreases systematically with increasing layer thickness. In order to ascertain the variation of the smoulder temperature as a function of layer thickness, tests can be performed with a layer thickness of 15 mm.

Since the ambient temperature strongly influences the temperature distribution inside the dust layer, ignition can occur on colder surfaces than determined in the standard test, if the ambient temperature is increased. Therefore, the value of the smoulder temperature cannot be used directly in warm environments, such as dryers.

- EN 50281: Electrical apparatus for use in the presence of combustible dust Part 2-1 Test methods -Methods for determining the minimum ignition temperatures of dust

- EN ISO/IEC 80079-20-2:2016: Explosive atmospheres Part 20-2: Material characteristics – Combustible dusts test methods, Section 8.2

- VDI-Richtlinien 2263, Blatt 1: Untersuchungsmethoden zur Ermittlung von sicherheitstechnischen Kenngrössen von Stäuben (1990)

- W. Bartknecht, Staub Explosionen: Ablauf und Schutzmassnahmen (1987)

- R.K. Eckhoff, Dust explosions in the process industries (1997)

- Explosion protection manual, Kluwer-Editorial